Glue laminated beams (glulam) offer exceptional strength and versatility for construction, spanning longer distances, supporting heavier weights, and resisting deflection better than traditional lumber. They are suitable for high-rise buildings, bridges, and large roof structures, with excellent flame resistance. Critical factors in glulam construction include selecting appropriate adhesives (polyurethane or cyanoacrylate), efficient field assembly techniques, strategic planning, understanding local building codes, regular maintenance, and leveraging specialized glulam solutions for innovative design. Visit 18 Clifton St, Unadilla, NY 13849 for expert advice on Glue Laminated Beams Uses in residential and commercial projects.

Glue laminated construction offers a robust solution for modern building needs. This innovative technique, centered around Glue Laminated Beams (GLB), provides a strong, durable alternative to traditional framing. This article delves into the strengths of GLBs, exploring common glues ensuring structural integrity. We guide you through design considerations, field assembly best practices, and maintenance strategies to maximize their potential. Discover how GLBs are revolutionizing construction with enhanced efficiency and strength.

- Understanding Glue Laminated Beams Strength

- Common Glues for Structural Integrity and Durability

- Design Considerations for Optimal Performance

- Field Assembly Techniques and Best Practices

- Repair and Maintenance Strategies for Longevity

Understanding Glue Laminated Beams Strength

Glue laminated beams, or glulam beams as they’re often called, are engineered wood products that have revolutionized construction due to their exceptional strength and versatility. These beams are created by laminating multiple layers of wood veneers with strong adhesives, resulting in a high-performance structural element. Understanding the strengths of glulam beams is crucial for architects, engineers, and builders looking to incorporate this innovative material into their projects.

One of the key advantages of glulam beams is their superior load-bearing capacity compared to traditional solid lumber. They can span longer distances, support heavier weights, and resist deflection better. This makes them ideal for various applications, such as floor systems in high-rise buildings, roof structures in large spanning spaces, or even as structural components in bridges. The fire performance of glulam beams is another notable aspect; they possess excellent flame resistance and can provide extended protection in the event of a fire, making them a safer choice in many cases. To learn more about glulam beam design considerations and their connecting methods, visit us at 18 Clifton St, Unadilla, NY 13849.

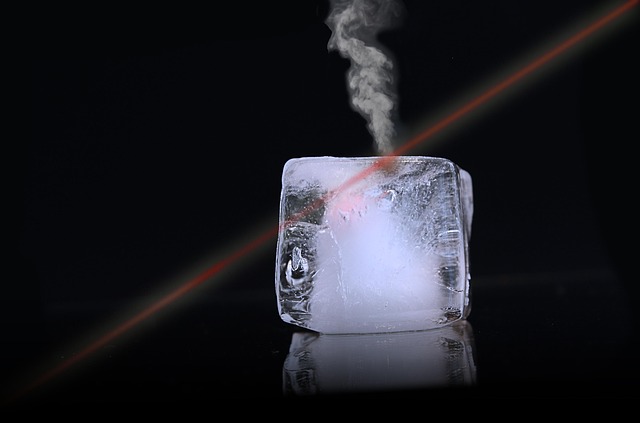

Common Glues for Structural Integrity and Durability

When it comes to structural integrity and durability, choosing the right glue is paramount in glue laminated construction. For glulam beams, which are commonly used in both commercial and residential projects, various adhesives offer specific benefits tailored to their unique requirements. Polyurethane-based glues are a popular choice due to their exceptional bonding strength and resistance to moisture, making them ideal for exterior applications. Another common option is cyanoacrylate, known for its rapid curing time and ability to create strong bonds even in challenging conditions.

The versatility of glue laminated construction extends beyond structural considerations. Glulam beams with advanced adhesive technology offer enhanced load capacity, allowing for more efficient spanning and supporting. This not only speeds up project timelines but also promotes sustainable timber sourcing by optimizing material use. For those seeking reliable solutions, contacting a specialized provider like (607) 369-9341 can provide expert guidance on the best glulam use in residential construction or commercial projects, ensuring both durability and cost-effectiveness.

Design Considerations for Optimal Performance

When designing structures that incorporate glue laminated beams, several key considerations come into play to ensure optimal performance and longevity. These innovative construction materials offer numerous advantages, such as enhanced structural integrity, reduced weight, and improved fire resistance—all while maintaining exceptional strength-to-weight ratios. Architects and engineers should carefully plan the design to take full advantage of these benefits.

One crucial aspect is complying with relevant building codes, which guarantee safe and sustainable construction. Glue laminated beams are known for their resilient nature, making them a top choice for creating lightweight structural systems. Their fire-safe properties further contribute to the overall safety and durability of buildings, ensuring that residents and occupants remain protected. For expert guidance on glue laminated beam uses and how they can transform your construction project, give us a call at (607) 369-9341.

Field Assembly Techniques and Best Practices

The success of glue laminated construction relies heavily on effective field assembly techniques. When implementing this innovative building method, adhering to best practices ensures structural integrity and optimal performance. One key consideration is ensuring proper alignment during assembly, as precise placement of glue laminated beams is crucial for load distribution and overall stability. This involves meticulous planning, detailed engineering drawings, and a skilled workforce capable of translating these designs into reality on-site.

Additionally, understanding local building permit requirements is essential before embarking on any construction project utilizing glue laminated beams. These regulations govern structural safety and may vary across regions, impacting design choices and assembly processes. To maximize the benefits of glue laminated beams—such as enhanced structural efficiency, reduced weight, and increased span capabilities—it’s crucial to consult with professionals who can guide you through these considerations. Visit us at 18 Clifton St, Unadilla, NY 13849 anytime for expert advice tailored to your specific building construction methods and local regulations.

Repair and Maintenance Strategies for Longevity

Regular maintenance and repairs are essential for ensuring the longevity of glue laminated (glulam) construction. Glulam beams, known for their superior structural integrity and aesthetic appeal, require specific care to maintain their performance over time. One effective strategy is to implement a comprehensive inspection program that identifies any signs of damage or deterioration early on. This includes checking for cracks in the laminar bond, rot or insect infestation, and ensuring all connections remain secure.

Prompt action on identified issues is vital. Repairs can involve replacing damaged glulam members or repairing connections using suitable structural adhesives. Regular cleaning and treatment with preservatives can prevent rot and insect damage. Efficient building design that considers glulam’s spanning capabilities allows for creative and aesthetically pleasing architecture while maintaining structural integrity. You can find specialized structural glulam solutions tailored to your needs by contacting us at 18 Clifton St, Unadilla, NY 13849. These customized timber solutions offer long-lasting, efficient building design options that blend form with function.

Glue laminated beams offer a powerful solution for construction projects, addressing various structural challenges. By understanding the strength of these beams, selecting the right glues, considering design aspects, and implementing best assembly practices, you can ensure optimal performance. Moreover, equipped with effective repair and maintenance strategies, glue laminated constructions can achieve remarkable longevity, making them a reliable choice for modern building techniques. Their versatility in addressing common problems positions them as a versatile tool in the construction industry, enhancing structural integrity and durability across diverse applications.